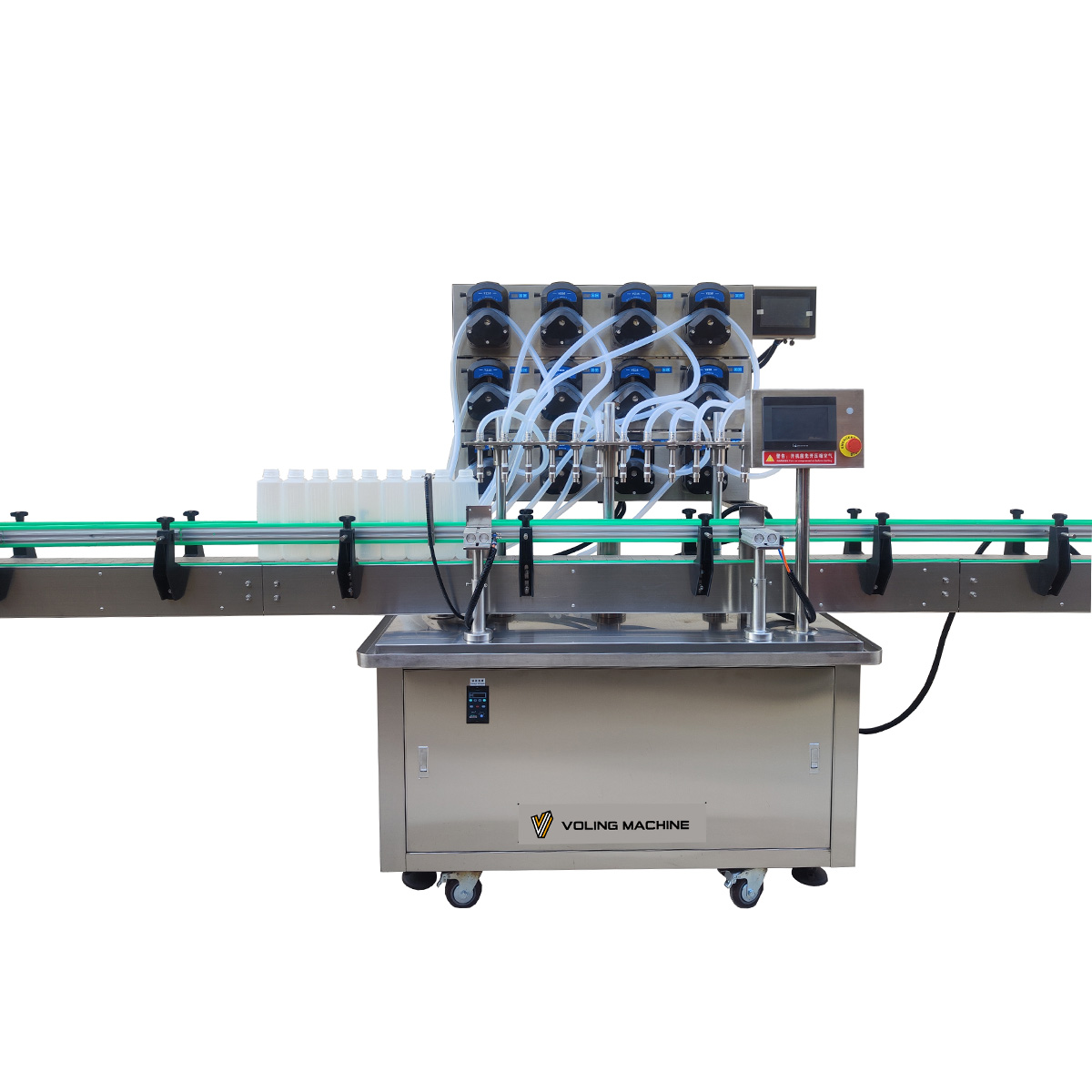

Automatic Linear Type Liquid Filling Machine

Applicable bottle: 30ml-1000ml

Applicable bottle types: glass bottles, plastic bottles, wide-mouth bottles, etc.

Production capacity: 40-60 bottles/ min, 80-100 bottles/min, 100-150 bottles/min, can be adjusted as per client’s requirements.

Filling precision: ≥98%

Voltage: 220V 50Hz

Power: 2KW

Air consumption: 0.8-2m³/h 0.3-0.8Mpa

Weight: 500KG

Dimensions: 2000*1250*1700mm, depends on detailed requirements.

Mô tả

The Automatic Linear Type Liquid Filling Machine is designed for efficient and precise filling of a wide range of liquid products, including both water-based and viscous fluids. It integrates high-precision piston or peristaltic pump filling with an automatic capping system, ensuring accurate and efficient production. Operating with high-speed linear motion, this machine offers fast production rates and supports the addition of multiple filling heads, making it highly scalable to meet varying output demands. It adopts multi-station synchronous filling (such as 4-16 filling heads working in parallel).

The filling head, conveyor belt, sealing device and other modules can be independently adjusted or replaced, which is convenient for flexible adaptation to different bottle types (such as containers of different heights and thicknesses). Compared to rotary filling machines, the linear type offers greater flexibility in bottle sizes and easier adjustment or maintenance, making it ideal for manufacturers with diverse product lines or frequent format changes.

The machine features advanced PLC control and a user-friendly touch screen interface for simple operation and precise parameter adjustment. Constructed with high-quality SUS304 or 316L stainless steel, it meets GMP standards and is widely used in the pharmaceutical, food and beverage, cosmetics, and chemical industries. It can also be seamlessly integrated with capping, labeling, and packaging systems to form a fully automated production line.

Features:

- PLC touchscreen control, multiple language set optional.

- Auto-stop when no bottle is detected and auto-start when bottles are present.

- High filling precision, optional multi-nozzle filling heads for higher output.

- Well-designed structure for smooth and stable operation.

- Customizable

- Made of SUS304 and 316L stainless steel, fully meeting the latest GMP standards.

Other matched equipments for filling lines: bottle feeder, bottle sorting, bottle washing, labeling, capping, sealing, counting, date inkjet printing, bottle boxing, sterilizing dryer, etc.