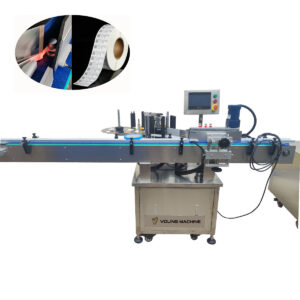

Automatic Cap Conveyor Machine for Package Filling Machine

Tasnif

The Cap Conveyor Machine is a critical component of automated filling and capping lines, designed to seamlessly transport matching caps to the capping station with high precision and stability. It supports various types of caps: screw caps, press-on caps, snap caps, pump caps, dropper caps, and more. The caps are loaded into a vibratory bowl feeder or elevator sorter, which automatically orients and aligns caps for accurate placement. It fits seamlessly into the automatic filling and packaging lines, reduces manual labor, and boosts productivity.

Features:

- The cap chute or pick-and-place robotic arm transfers the oriented caps directly above the waiting bottles.

- Ensures caps are sorted and oriented correctly for fast and accurate placement.

- Made of SUS304 or SUS316L stainless steel, resistant to corrosion and easy to clean. Complies with GMP standards, making it suitable for pharmaceutical and food-grade environments.

Other matched equipments for filling lines: bottle feeder, bottle sorting, bottle washing, liquid filling, labeling, sealing, counting, date inkjet printing, bottle boxing, sterilizing dryer, etc.

Applicable industry

Pharmaceuticals: Syrups, eye drops, oral solutions

Cosmetics: Lotions, creams, essential oils

Food & Beverage: Juice, sauce, condiments

Chemical & Personal Care: Detergents, disinfectants, hand sanitizers