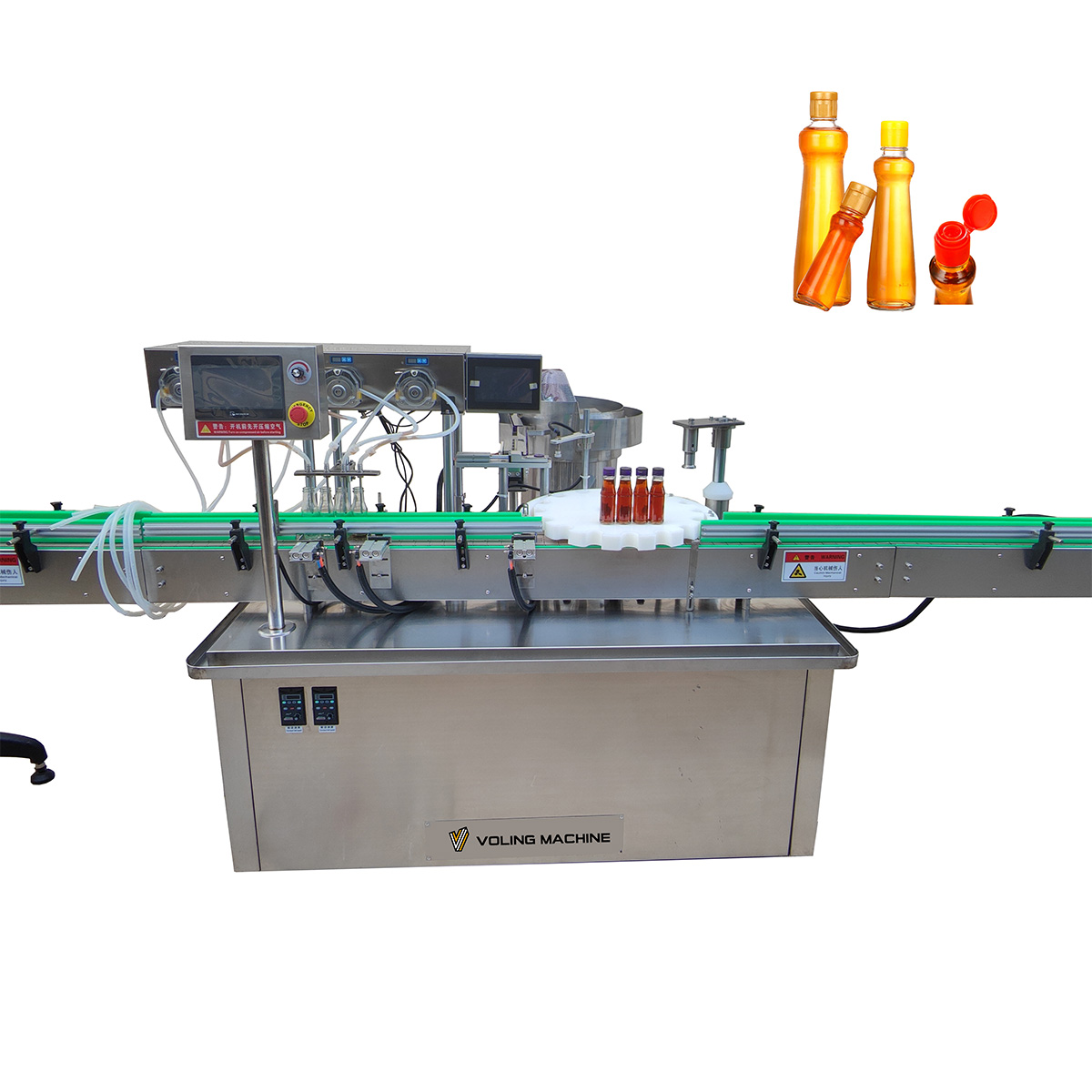

Oil Vinegar Seasoning Bottle Filling Machine

Applicable bottle: 1-1000ml

Production capacity: 30-50 bottles/ min, 60-80 bottles/min, can be adjusted as per client’s requirements.

Voltage: 220V 50Hz or according to customer’s demand

Power: 3KW

Air consumption: 0.8-2m³/h 0.3-0.8Mpa

Weight: 550KG

Dimension: 5600*1500*1700mm

Descriere

This oil and vinegar bottle automatic filling and capping machine is designed for filling edible oil, olive oil, vinegar, salad dressings, and other seasoning liquids into bottles with high efficiency and precision. It is suitable for both low and medium viscosity products and supports high-precision piston or peristaltic pump filling with an automatic capping system filling systems depending on product type.

The machine features a PLC control system with a touch screen interface for easy operation. It supports multiple bottle sizes and is equipped with an anti-drip filling nozzle to ensure cleanliness. It can be customized with different numbers of filling heads and capping styles based on bottle type and product characteristics. The capping unit accommodates various types of caps—plastic screw caps, press-on caps, and metal twist caps—with adjustable torque for a secure seal. Made of food-grade stainless steel, the machine fully complies with GMP and food safety standards, making it the ideal choice for filling oil, vinegar, salad sauce and seasoning liquids.

Features:

- Easy replacement of parts with an automatic cleaning function.

- PLC touchscreen control, multiple language set optional.

- Auto-stop when no bottle is detected and auto-start when bottles are present.

- High quality cam indexer ensures precise workstation division for stable filling, stoppering, cap placement, and capping.

- High filling precision, optional multi-nozzle filling heads for higher output.

- Well-designed structure for smooth and stable operation.

- Customizable

- Easy to replace molds, suitable for various capacity of bottles production.

- Made of SUS304 and 316L stainless steel, fully meeting the latest GMP standards.

Other matched equipments for filling lines: bottle feeder, bottle sorting, bottle washing, labeling, capping, sealing, counting, date inkjet printing, bottle boxing, sterilizing dryer, etc.