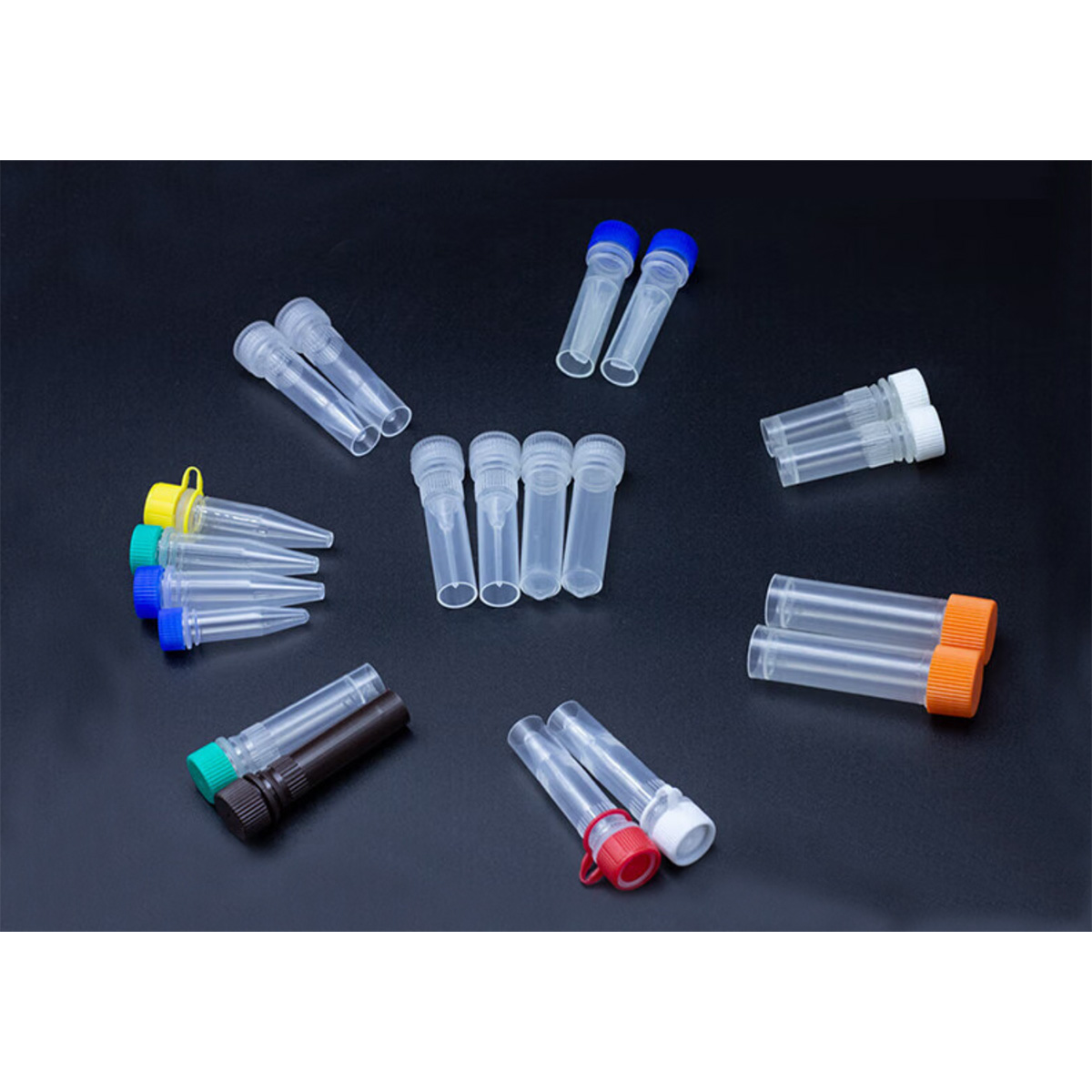

Sampling Tube Cryogenic Tube Automatic Filling and Capping machine

Applicable bottle: 2ml-10ml

Production capacity: 30-40 bottles/min, 60-80 bottles/min, can be adjusted as per client’s requirements.

Voltage: 220V 50Hz

Power: 2KW

Air consumption: 0.8-2m³/h 0.3-0.8Mpa

Weight: 550KG

Dimensions: 2000*1250*1700mm

Descrição

Designed for fully automatic filling of various diagnostic reagents, in-vitro diagnostic (IVD) reagents, and nucleic acid test reagents. It provides a professional reagent filling solution, with optional ISO Class 5 (100-grade) laminar flow and a specialized aseptic filling machine design. Featuring high automation, the system ensures no filling, no stoppering, and no capping without bottles.

Features:

- Intelligent PLC Control – Equipped with a smart human-machine interface, supporting multi-language options for an intuitive and user-friendly operation.

- Photoelectric Sensor for Precision Filling – Utilizes imported German photoelectric sensors to accurately detect bottle positions, ensuring precise filling.

- High-Quality Integrated Circuit – Built with premium domestic and international components, ensuring reliable performance and long-lasting durability.

- Anti-Drip Filling Nozzles – Features high-quality anti-drip filling nozzles with adjustable positions and customizable nozzle numbers based on production needs.

- Durable High-Performance Cylinders – The machine is equipped with high-quality cylinders, offering long service life and high efficiency.

- Air Inlet with Pressure Gauge – Designed with a switch-controlled air inlet and built-in pressure gauge for easy air supply adjustment and efficient operation.

- Seamless Chain Conveyor – Features a seamless chain conveyor, compatible with various bottle diameters, with adjustable side guards for smooth and stable bottle transportation.