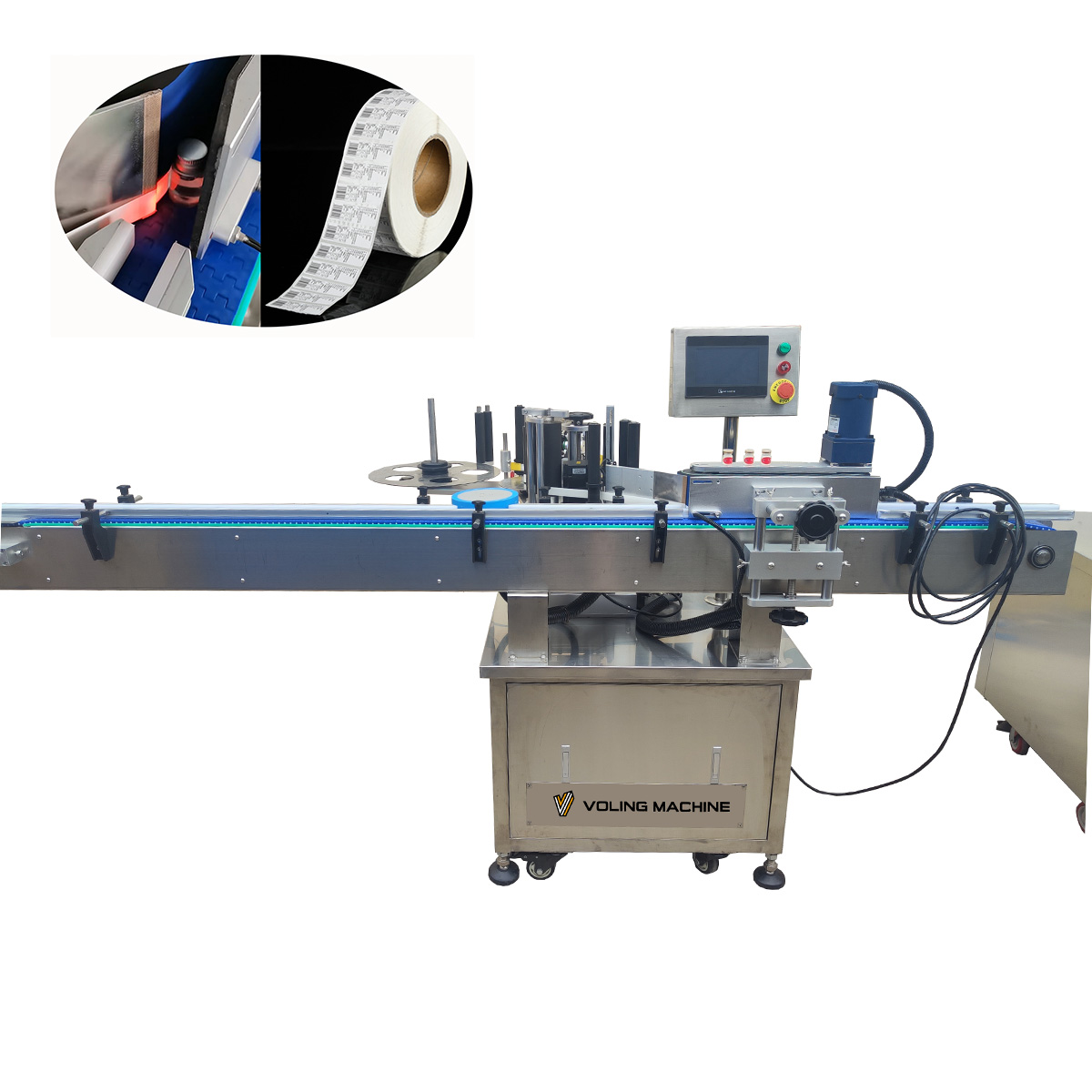

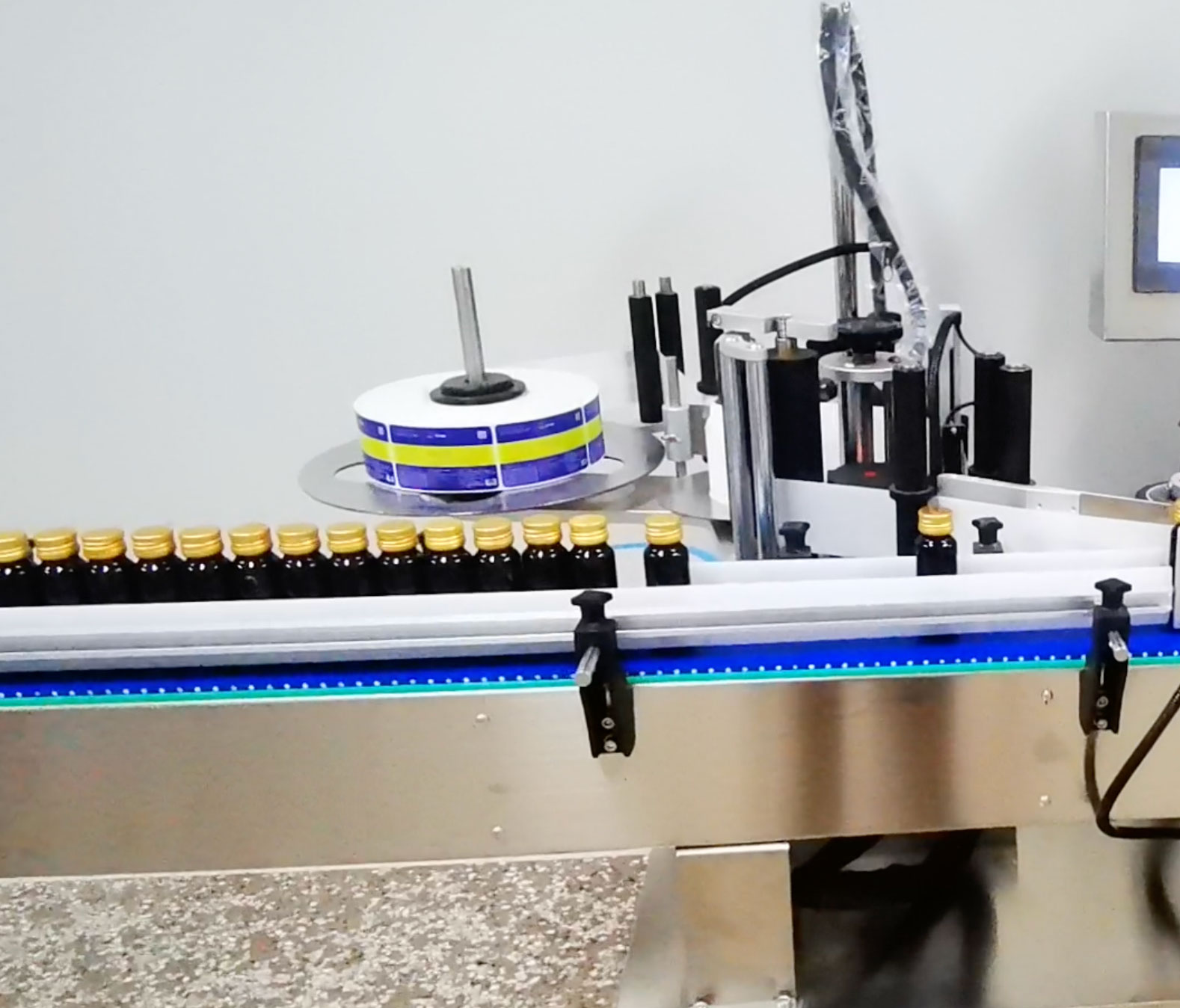

Automatic Induction Labeling Machine

Description

The automatic labeling machine is the supporting equipment of the filling production line, which is used to precisely, efficiently and automatically attach labels (such as product description, names, ingredients, barcodes, etc.) on the surface of the bottles or cans after filling. Its core functions include label conveying, positioning, lamination and detection, ensuring that the labels are accurately positioned, free of bubbles and wrinkles, ensures products maintain a professional, uniform appearance, enhance production efficiency. It meets the high-standard production requirements of the food, beverage, pharmaceutical, daily chemical and other industries.

Features:

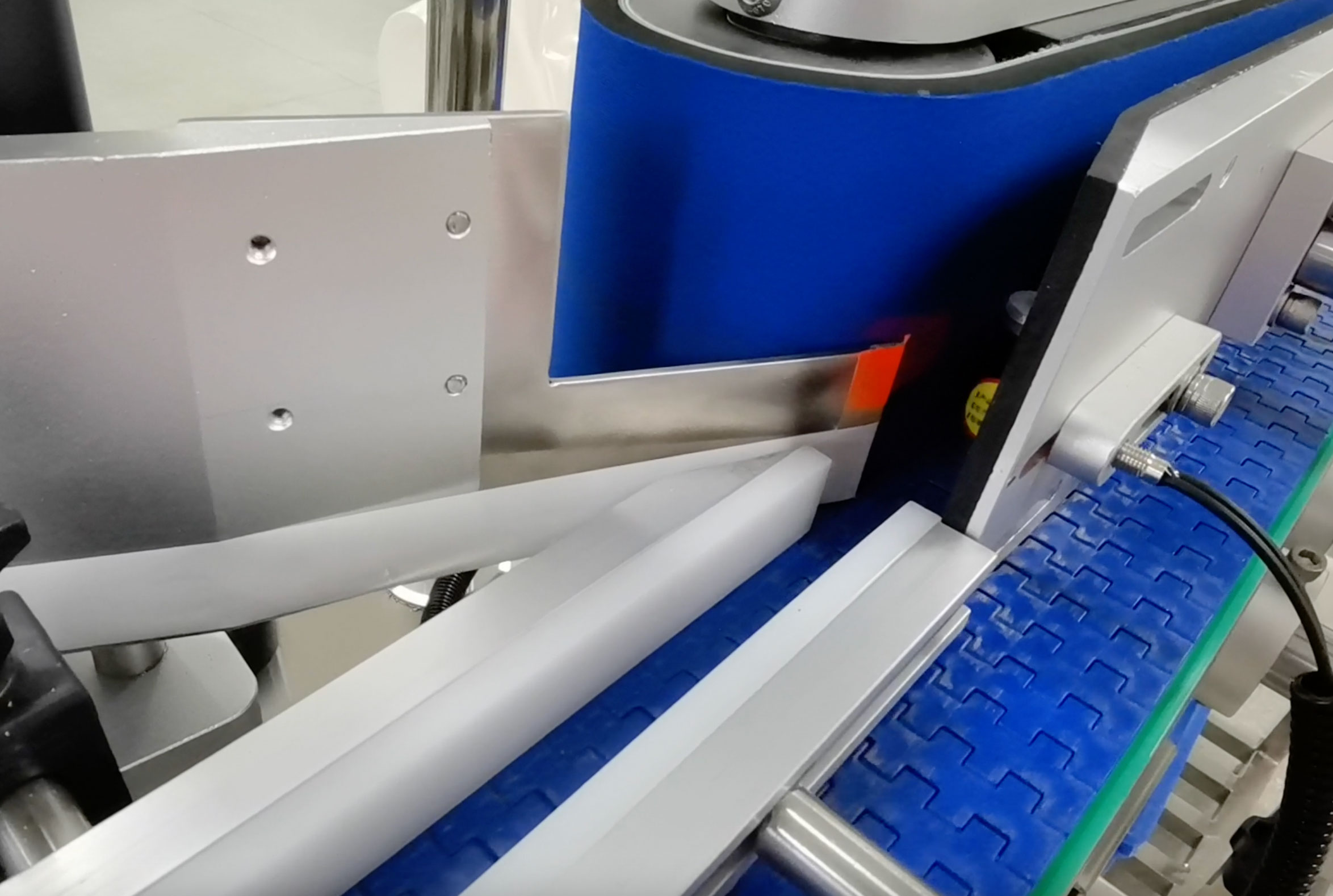

- Supports self-adhesive labels, film labels, etc. The width of the roll material is adjustable, the height and angle of the label are adjustable to match different bottle sizes.

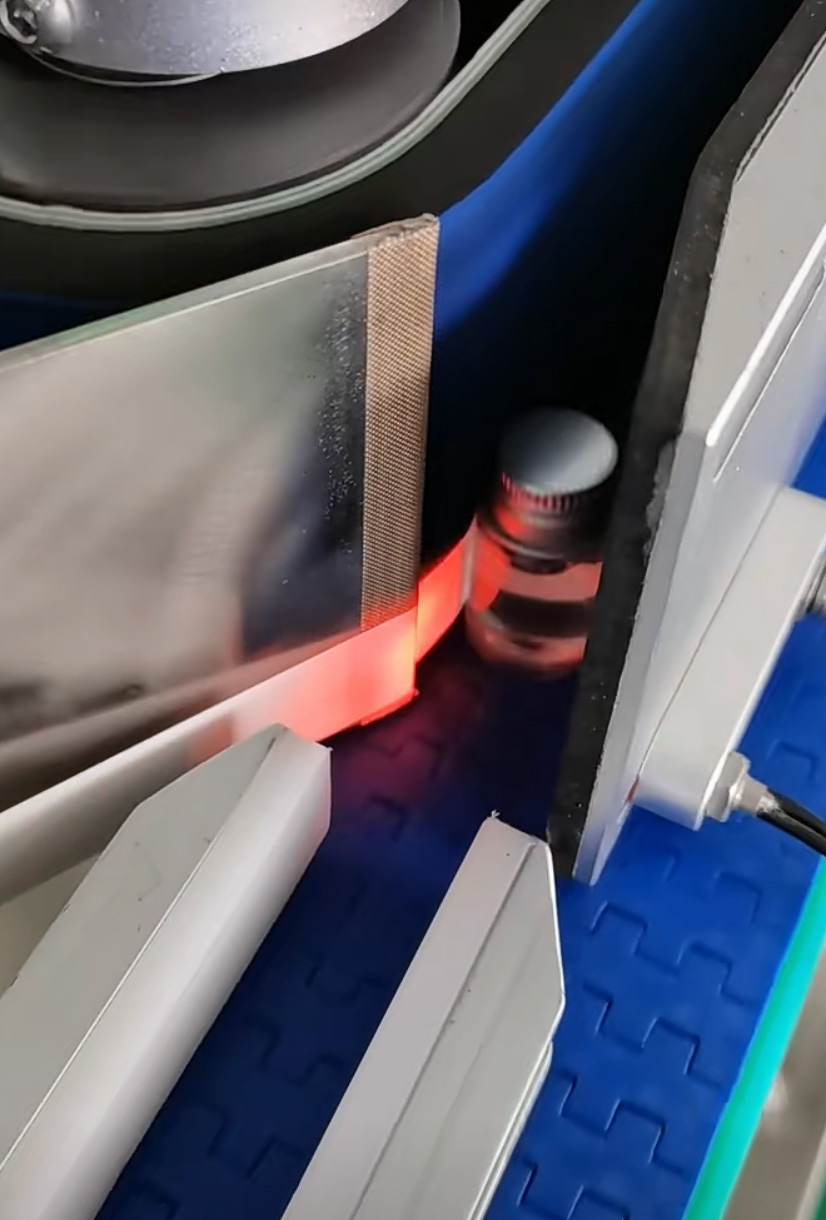

- Automatically peel off the backing paper and precisely release the label, no breaking or wrinkling.

- High precision and consistent placement, label position error is ≤0.5mm.

- Features optical sensors to detect bottle and label presence, ensuring “no-label/no-bottle, no-label” operation.

Other matched equipments for filling lines: bottle feeder, bottle sorting, bottle washing, liquid filling, capping, sealing, counting, date inkjet printing, bottle boxing, sterilizing dryer, etc.