-

The automatic bottle feeder is the core auxiliary equipment of the liquid and powder filling production line. It is used to automatically and orderly transport empty bottles (such as plastic bottles, glass bottles, etc.) to the filling station of the filling machine, achieving seamless connection with the filling machine. Its core function is to enhance production efficiency, reduce manual intervention and ensure the stability of the filling process. It is widely used in industries such as beverages, daily chemicals, pharmaceuticals and edible oil. Features: Automatically organizes and feeds various shapes and sizes of plastic or glass bottles. Supports continuous high-volume bottle feeding, improving production line efficiency. Can be customized to handle different bottle…

-

The automatic bottle arranging machine is the core equipment at the front end of the liquid filling production line. It is mainly used to automatically organize the disordered empty bottles into a unified direction and upright arrangement, and stably transport them to subsequent equipment such as automatic filling machines, capping or labeling machines. Its core function is to enhance production efficiency, reduce manual intervention and ensure the stability of the filling process. It can handle round bottles, square bottles, and irregular-shaped bottles. The contact surface material is made of 304 stainless steel or food-grade PP, meeting GMP and FDA standards. It is commonly used in industries such as pharmaceuticals, cosmetics, food…

-

The Cap Conveyor Machine is a critical component of automated filling and capping lines, designed to seamlessly transport matching caps to the capping station with high precision and stability. It supports various types of caps: screw caps, press-on caps, snap caps, pump caps, dropper caps, and more. The caps are loaded into a vibratory bowl feeder or elevator sorter, which automatically orients and aligns caps for accurate placement. It fits seamlessly into the automatic filling and packaging lines, reduces manual labor, and boosts productivity. Features: The cap chute or pick-and-place robotic arm transfers the oriented caps directly above the waiting bottles. Ensures caps are sorted and oriented correctly for fast…

-

The automatic induction aluminum foil sealing machine is specifically designed for non-contact, efficient and hygienic aluminum foil sealing of the mouths of plastic bottles, glass bottles and other containers at the end of the filling production line. This equipment adopts the principle of induction heating and can achieve the instantaneous fusion of aluminum foil films without touching the bottle mouth, forming a sealing layer with excellent air tightness. It can seamlessly integrated into filling and packaging lines. It is widely used in industries such as pharmaceuticals, food and beverage, cosmetics, chemicals, and nutraceuticals. Features: User-friendly control panel for real-time parameter setting and monitoring, including sealing temperature, power, and conveyor speed….

-

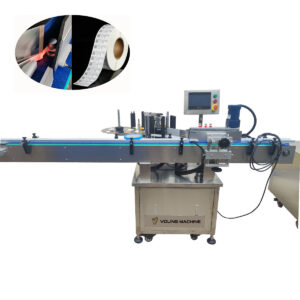

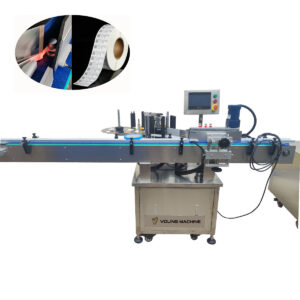

The automatic labeling machine is the supporting equipment of the filling production line, which is used to precisely, efficiently and automatically attach labels (such as product description, names, ingredients, barcodes, etc.) on the surface of the bottles or cans after filling. Its core functions include label conveying, positioning, lamination and detection, ensuring that the labels are accurately positioned, free of bubbles and wrinkles, ensures products maintain a professional, uniform appearance, enhance production efficiency. It meets the high-standard production requirements of the food, beverage, pharmaceutical, daily chemical and other industries. Features: Supports self-adhesive labels, film labels, etc. The width of the roll material is adjustable, the height and angle of the…

-

The Automatic Inkjet Printing Machine is an essential component of modern filling and packaging production lines. Designed for high-speed, non-contact marking, this machine delivers precise, clear, and reliable coding on a wide variety of packaging materials, such as plastic bottles, glass containers, cartons, labels, and more. Integrated seamlessly into the filling production line, it can automatically detect and print production dates, batch numbers, barcodes, QR codes, logos, or custom text in real time. Features: Uses photoelectric sensors or encoder systems to ensure printing is only applied when a product is present, improving efficiency and preventing errors. Supports printing on plastic, glass, metal, paperboard, and flexible film—ideal for pharmaceuticals, cosmetics, beverages,…

-

Applicable bottle: 30ml-1000ml

Applicable bottle types: glass bottles, plastic bottles, wide-mouth bottles, etc.

Production capacity: 40-60 bottles/ min, 80-100 bottles/min, 100-150 bottles/min, can be adjusted as per client’s requirements.

Filling precision: ≥98%

Voltage: 220V 50Hz

Power: 2KW

Air consumption: 0.8-2m³/h 0.3-0.8Mpa

Weight: 500KG

Dimensions: 2000*1250*1700mm, depends on detailed requirements.

-

The Bottle Washing and Drying Machine is an essential piece of equipment in modern production lines, designed to efficiently clean and dry bottles before filling or packaging. It ensures that all containers bottles or jars are free from dust, particles, and microbial contaminants, meeting stringent hygiene and quality standards in industries such as pharmaceuticals, food & beverage, cosmetics, and chemicals. This machine can be used as a standalone unit or integrated into fully automated filling and packaging lines, significantly enhancing production cleanliness and efficiency. Core function: Deep cleaning – Remove dust, oil stains and residues both inside and outside the bottle. Sterilization and disinfection – Chemical disinfection or high-temperature rinsing…

-

Applicable bottle: 1-500ml

Production capacity: 30-40 bottles/min, 60-80 bottles/min, can be adjusted as per client’s requirements.

Voltage: 220V 50Hz

Power: 2.0KW

Air consumption: 0.8-2m³/h 0.3-0.8Mpa

Weight: 500KG

Dimensions: Filling machine 2000*1250*1700mm, others parts optional.