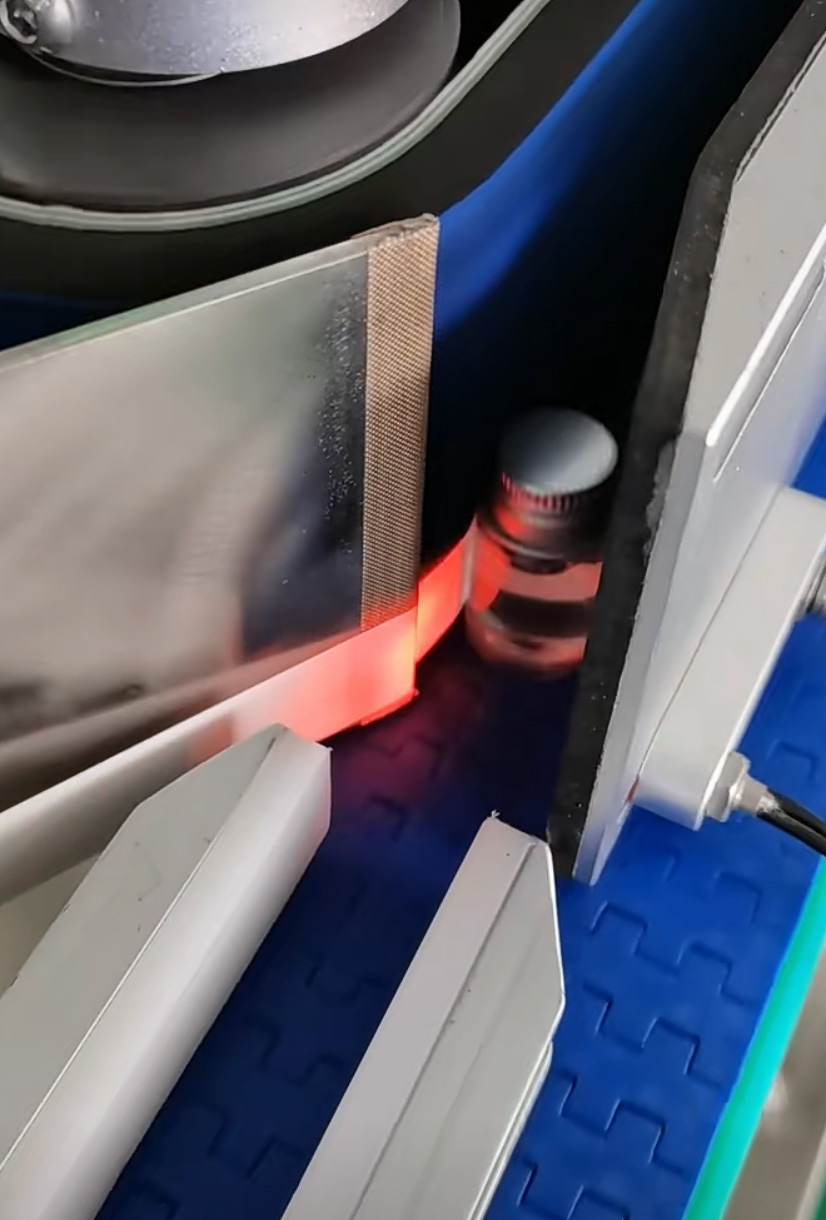

Pharmaceutical Vial Bottle Liquid Filling Machine Production Line

Applicable bottle: 1-50ml

Production capacity: 30-40 bottles/min, can be adjusted as per client’s requirements.

Voltage: 220V 50Hz

Power: 2.0KW

Air consumption: 0.8-2m³/h 0.3-0.8Mpa

Weight: 500KG

Dimensions: 2000*1250*1700mm, others parts optional.

Descripció

The vial liquid filling production line mainly consists of an automatic bottle washing machine, a tunnel sterilization oven, a vial filling and capping machine, a labeling machine, and other equipment. It adopts PLC control, touch screen operation, and peristaltic pump filling, ensuring high filling accuracy. The entire production line is manufactured in full compliance with the GMP standards and is widely used in the pharmaceutical, food, healthcare, and chemical industries.

Features:

- High quality cam indexer ensures precise positioning for filling, stoppering, and capping.

- Peristaltic pump filling with PLC touchscreen control for high accuracy and easy operation, multiple language set optional.

- Frequency conversion control allows adjustable speed.

- Automatic stop function when no bottle is detected; filling resumes automatically when bottles are present.

- Produced with SUS304 and 316L stainless steel, fully compliant with the latest GMP standards.

- Customizable

- Easy to replace molds, suitable for various capacity of bottles production.

Other matched equipments for filling lines: bottle feeder, bottle sorting, bottle washing, labeling, capping, sealing, counting, date inkjet printing, bottle boxing, sterilizing dryer, etc.